Choosing the Right Forklift Safety System Provider

Forklifts are essential to modern industrial operations but they also pose serious safety risks when not properly managed. With rising workplace safety standards and stricter compliance requirements, choosing the right AI-powered forklift safety provider is no longer optional, it’s critical. The right solution can help prevent costly accidents, reduce downtime, and protect both workers and equipment. .

In this guide, we’ll walk you through the key factors to consider when selecting a provider that delivers real, measurable safety results.

Why Forklift Safety Systems Matter

Forklifts are involved in thousands of workplace incidents each year. According to OSHA, approximately 85 fatal forklift accidents occur annually in the U.S., with nearly 35,000 incidents resulting in serious injuries. These incidents not only cause harm to workers but also lead to significant financial consequences for companies.

The true cost of ignoring forklift safety goes beyond medical expenses. Companies face regulatory fines, legal fees, increased insurance premiums, and reputational damage. Additionally, downtime caused by accidents can severely impact productivity and supply chain operations.

According to the National Safety Council in the USA, the direct costs are estimated up to $1.4 million per death. In addition to these direct costs, there are also indirect costs such as workplace disruptions, loss of productivity, replacement of the employee, training of the replacement, and increased insurance premiums. These indirect costs can represent up to 17 times the direct costs.

Modern forklift safety systems play a vital role in proactively reducing risk and prevent accidents. By integrating advanced detection technology, operators gain greater awareness of their surroundings, especially in busy or blind spot–ridden environments. These systems act as a co-pilot, alerting drivers before incidents occur.

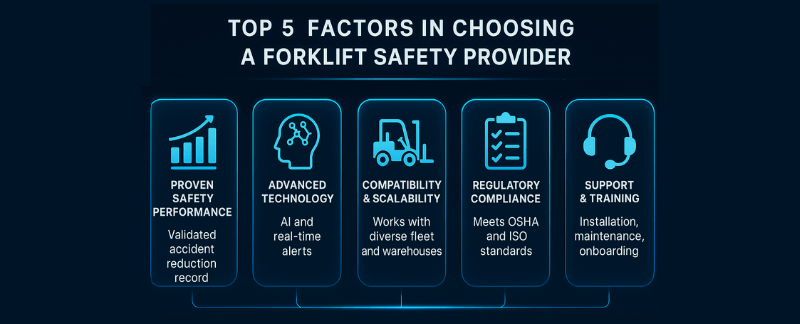

Top Criteria for Choosing a Forklift Safety Provider

Proven Safety Performance with Real Results

Safety claims are easy to make, but only a few providers can back them with data. Look for companies with a proven track record of improving safety outcomes in real-world environments such as warehouses, factories, and construction sites.

Leading providers often present case studies showing significant reductions in near-misses and pedestrian collisions after system deployment. These metrics are crucial for justifying investment and gaining internal stakeholder buy-in.

Advanced Technology: AI and Real-Time Detection

Not all detection systems are created equal. Many rely on ultrasonic or radar sensors that trigger frequent false alarms, leading to operator fatigue or even system deactivation.

AI-based systems, such as Blaxtair’s pedestrian detection technology, go a step further by using computer vision to recognize and distinguish between people and objects in real time. This accuracy drastically reduces false alerts while keeping operators focused.

Real-time alerts in forklift operations are especially valuable in high-traffic areas, blind spots, or environments with poor lighting. The system notifies the driver only when there’s a true risk, increasing trust and adoption.

System Compatibility and Scalability

A forklift safety solution must be versatile enough to fit your existing fleet and scalable to grow with your operations.

- Compatibility: Ensure the system works on a variety of forklift brands and models: electric, gas, or diesel.

- Scalability: Can it be rolled out across multiple facilities or vehicle types (e.g., loaders, excavators, reach trucks)

- Future-proofing: Leading systems integrate with telematics platforms, fleet management software, and warehouse management systems (WMS) to give safety managers full visibility and traceability.

This flexibility is key in mixed-use industrial environments such as warehouses, logistics hubs, construction sites, and open-pit quarries.

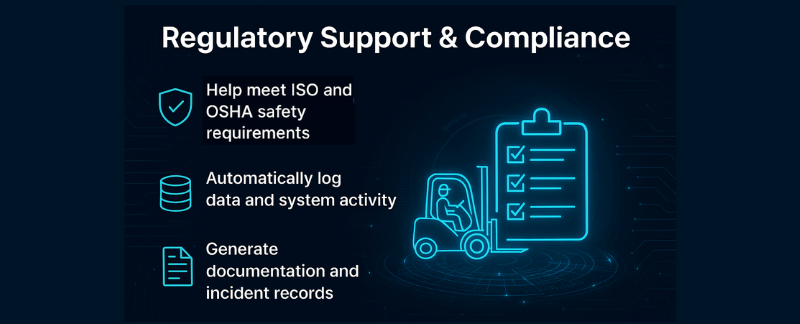

Regulatory Support and Compliance

Industrial sites are under increasing scrutiny when it comes to safety standards. A strong AI-powered forklift safety provider should support your compliance strategy at every level.

The right solution will:

- Help meet ISO and OSHA safety requirements

- Automatically log data and system activity for internal reporting or external audits

- Generate documentation and incident records that simplify safety assessments and inspections

This not only reduces your compliance burden but helps build a culture of safety across the organization.

Local Support, Training & Maintenance

Even the most advanced system can fall short without proper onboarding and maintenance. A reliable safety provider should offer:

- Installation support, either on-site or through certified partners

- Technical diagnostics and remote troubleshooting

- Comprehensive training programs to ensure team adoption and effectiveness, including operator and maintenance training with multilingual materials or in-person sessions

- Ongoing updates, replacements, and upgrade paths for evolving needs

Compliance and Regulatory Considerations

Compliance isn’t just about avoiding penalties, it’s about proactively ensuring a safe and legally sound work environment.

When choosing a provider, verify that their solutions meet:

- OSHA directives related to machinery and workplace safety

- ISO standards for safety systems and risk reduction

- Any regional or national regulations relevant to your operations

Top-tier providers assist in creating documentation packages, offer automated reporting features, and support audits or safety assessments with confidence.

Comparing Providers: Key Questions to Ask

Before committing to a provider, ask the following questions:

- What type of detection technology is used: AI, radar, ultrasonic?

- Does the system provide real-world data proving accident or near-miss reductions?

- Can the system distinguish between pedestrians and other objects?

- Is training available to ensure smooth adoption by forklift drivers?

- What is the average time required for installation and operator training?

- What post-installation support is offered?

- How does the solution integrate with your existing safety programs or digital tools?

Answers to these questions can reveal both the technical sophistication and service quality of each potential partner.

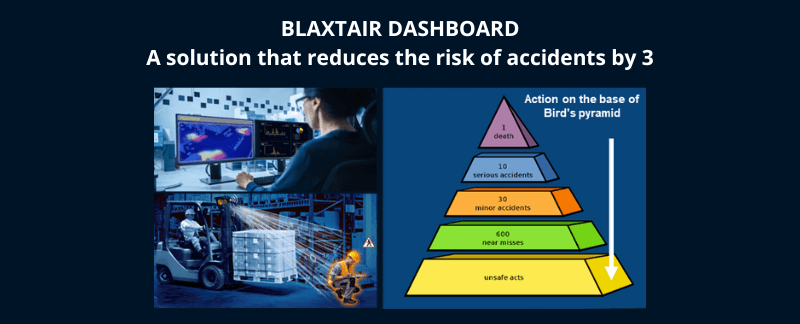

Why Blaxtair Stands Out

Among the various options on the market, Blaxtair remains a pioneer in AI-powered forklift safety.

Here’s what sets Blaxtair apart:

- Unique AI Camera: The only embedded system that reliably distinguishes pedestrians from obstacles in real time

- Proven Impact: Real-world deployments show a reduction of the risk of accidents upstream by 3 on the first sites of use

- Versatile Use Cases: Trusted in warehouses, logistics, mining, recycling, quarrying and construction industries

- Regulatory Strength: Supports full compliance with international safety standards

- Global Presence: With active support teams and integration experts across Europe, North America, and Asia

- Connected Platform: Seamlessly integrates with telematics and fleet management systems

Conclusion

Choosing the right forklift safety system provider can drastically reduce risks, protect your workforce, and improve operational continuity. It’s not just about installing a sensor, it’s about building a comprehensive safety ecosystem.

Don’t settle for outdated, one-size-fits-all systems. Instead, opt for advanced, AI-powered, real-time solutions that adapt to your operational needs and scale with your growth.

Contact Blaxtair today to learn how our intelligent safety systems can help protect your people and productivity.