OSHA-Ready Vehicle Inspections: Digitize Daily Checks in Minutes

Daily inspections are a core requirement for safe industrial vehicle operation—but paper-based processes often fail when speed, accountability, and audit readiness matter most. In busy warehouses, logistics hubs, recycling sites, and manufacturing plants, operators need a simple way to complete OSHA vehicle inspection checklists consistently, without chasing clipboards or managing stacks of paper.

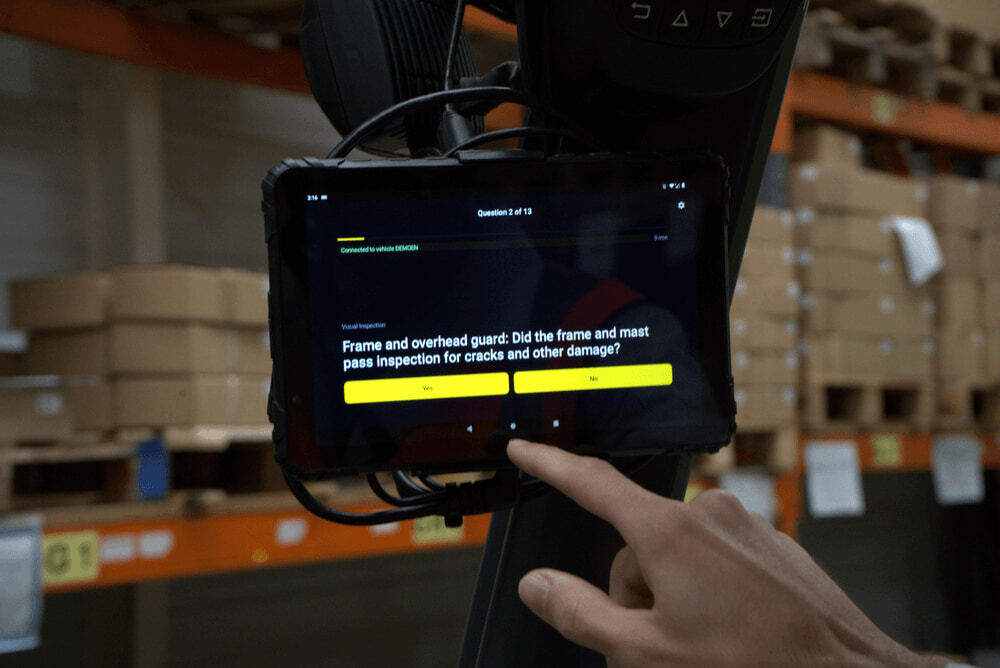

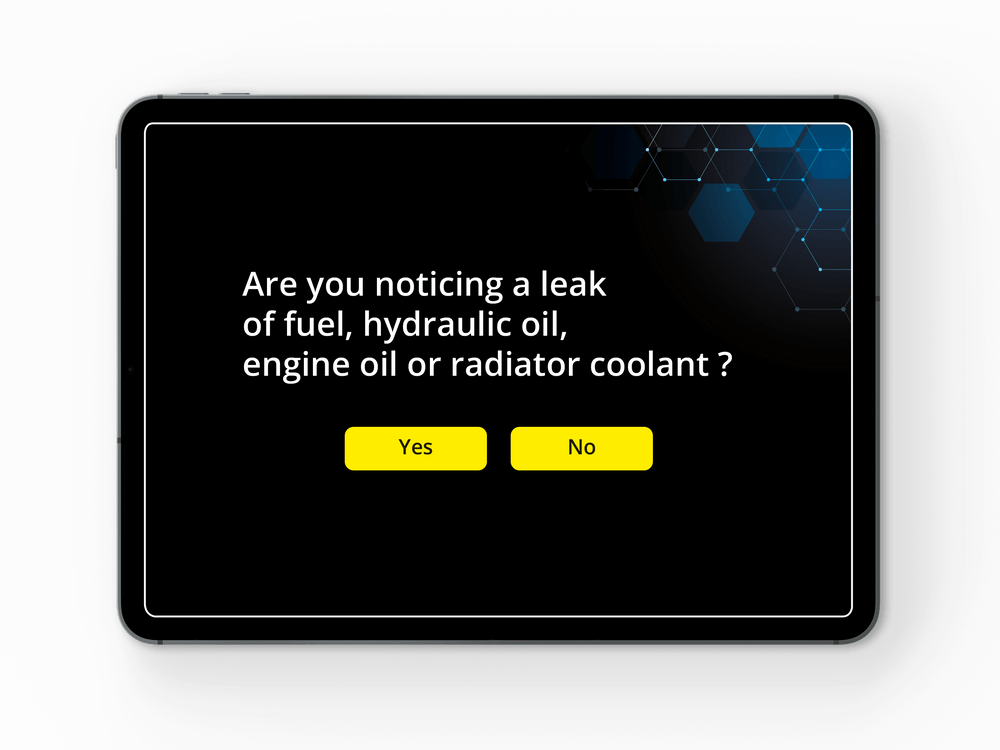

Blaxtair Checklist digitizes OSHA-driven inspections directly on an in-cab screen adapted to industrial vehicles. Operators are guided step by step through customizable pre-start checks, while every inspection automatically generates a traceable compliance record. The result: faster inspections, fewer missed defects, and stronger safety control across the fleet.

Why Daily Equipment Inspections Are a Compliance Must

Every industrial vehicle—from forklifts and pallet trucks to loaders and yard vehicles—must undergo vehicle pre-start safety checks before operation. OSHA regulations require employers to ensure equipment is in safe working condition and that inspections are properly documented.

Despite this, many operations still struggle with compliance due to outdated processes. Common risks include:

- Missing or incomplete inspection records

- Inconsistent checks across shifts or sites

- Backfilled or illegible paperwork

- Time lost collecting, storing, and auditing forms

Without reliable, time-stamped inspection data, companies expose themselves to fines, downtime, and liability when incidents occur.

The Problem With Paper Checklists

Paper-based inspection systems no longer align with the pace or accountability requirements of modern industrial operations.

Typical challenges include:

- Operators rushing or skipping checks during shift changes

- Paper logs that are lost, damaged, or never filed

- No real-time visibility for supervisors or safety managers

- No automated link between inspections and maintenance actions

When an audit or incident occurs, paper makes it difficult to prove compliance or demonstrate proactive risk prevention.

The Digital Solution: Blaxtair Checklist

Blaxtair Checklist brings daily inspections into the digital era with a smart, vehicle-mounted touchscreen interface designed for industrial environments.

Operators complete their OSHA vehicle inspection checklist directly from the cab at the start of each shift. Each inspection is guided, requires operator identification, and is securely stored in the cloud for instant access by safety and maintenance teams.

If a defect or unsafe condition is reported, the system can escalate it immediately—transforming inspections from a formality into an enforceable safety control.

Key Features That Simplify OSHA Compliance

- Vehicle-Mounted Touch Display

Inspections completed from the cab in minutes—no paper, no extra devices. - Customizable Digital Checklists

Adapt questions by vehicle type, site, or regulatory requirements. - Cloud-Based, Traceable Records

Every inspection is time-stamped, stored, and audit-ready. - Smart Alerts for Non-Conformities

Reported defects automatically notify supervisors or maintenance teams. - Optional Start Prevention

Vehicles can be configured not to start if critical issues are flagged. - Operator Identification & Accountability

Each inspection is linked to a verified driver.

Together, these features turn regulatory compliance into a fast, consistent, and reliable daily process.

Built for Multi-Vehicle Fleets and Evolving Operations

One of the most important advantages of a cloud-based digital checklist is its ability to scale with operational complexity.

Industrial sites rarely operate a single type of vehicle. Forklifts, reach trucks, loaders, terminal tractors, and specialized equipment often coexist—each with different inspection requirements. Managing this diversity with paper checklists quickly becomes inefficient and error-prone.

Vehicle-Specific Checklists for Mixed Fleets

Blaxtair Checklist allows companies to create and manage dedicated inspection checklists for each vehicle type, based on:

- Vehicle category (forklift, loader, yard vehicle, etc.)

- Specific models or manufacturers

- Site-specific risks and operating conditions

- Internal safety standards or regulatory constraints

Operators are automatically presented with the correct checklist for the vehicle they are operating, reducing the risk of skipped steps or incorrect inspections.

This ensures consistency and compliance across mixed fleets, even in large or multi-site operations.

Update Checklists Anytime—With Minimal Operational Impact

Safety requirements evolve. Regulations change. Equipment configurations and site layouts are updated. Paper checklists make these changes slow and disruptive.

With a cloud-based system, checklist updates can be:

- Created or modified centrally

- Deployed instantly across one vehicle, one site, or the entire fleet

- Applied without reprinting forms or disrupting operations

This flexibility allows safety teams to respond quickly to:

- New OSHA guidance

- Lessons learned from incidents or near-misses

- Changes in equipment or operational procedures

Inspections become a living safety process, not a static document.

Meeting OSHA and Global Compliance Requirements

OSHA mandates daily or pre-shift inspections for powered industrial vehicles. Failure to comply can result in significant penalties—especially if an unreported defect contributes to an accident.

Digital inspection systems help organizations:

- Prove inspections were completed before vehicle use

- Demonstrate corrective actions for reported defects

- Maintain centralized records across sites and fleets

- Reduce audit stress and administrative workload

Instead of scrambling for paperwork, safety managers gain immediate access to inspection histories and trends.

Beyond Compliance: Operational Benefits of Digital Inspections. Measurable ROI

Digitizing daily inspections doesn’t just support OSHA requirements—it improves overall operations:

- Reduced Downtime through early defect detection

- Faster Shift Changes with inspections completed in minutes

- Stronger Safety Culture through accountability and consistency

- Better Maintenance Planning using real inspection data

When inspections are easy to complete and enforced by design, operators are far more likely to perform them correctly—every shift.

Expert Insight on Digital Inspections

“Digitized vehicle inspections are no longer a luxury — they’re a compliance necessity. With Blaxtair Checklist, every check becomes traceable, auditable, and instantly actionable.”

— Blaxtair Safety Systems Engineering Team

This expert perspective reflects a broader shift across industrial safety programs: compliance today depends on data integrity, traceability, and real-time action, not paperwork alone. Digital inspection systems help organizations demonstrate due diligence during audits, investigations, and insurance reviews—while actively reducing operational risk on the floor.

How Blaxtair Checklist Fits Into a Broader Safety Strategy

Blaxtair Checklist integrates seamlessly with connected safety and fleet solutions. Inspection data can complement collision avoidance systems, pedestrian detection, and fleet monitoring tools—creating a unified, data-driven approach to industrial vehicle safety.

This allows companies to move from reactive compliance to proactive risk prevention.

Ready to Modernize Your OSHA Vehicle Inspection Checklist?

Paper inspections slow teams down and leave compliance gaps. Blaxtair Checklist provides a faster, smarter way to manage vehicle pre-start safety checks—directly from the cab, with full traceability.

Contact a Blaxtair expert today to see how digital inspections can simplify compliance and strengthen workplace safety across your fleet.

FAQs

Why are daily vehicle inspections required by OSHA?

Daily vehicle inspections are required by OSHA to ensure that industrial vehicles are safe to operate. Completing these checks before each shift helps prevent accidents, reduce mechanical failures, and maintain regulatory compliance.

How does Blaxtair Checklist help ensure compliance?

Blaxtair Checklist helps ensure compliance by digitizing pre-use checks directly on a vehicle-mounted screen. Every inspection is time-stamped, stored in the cloud, and linked to the operator’s ID—creating a traceable record for audits and insurance.

Can the system prevent a vehicle from starting after a failed inspection?

Yes. Blaxtair Checklist can be configured to restrict vehicle start-up when an unsafe condition or failed inspection is detected, ensuring that noncompliant vehicles never enter operation.