Forklift Checklist: The Ultimate Guide to Daily Safety Inspections

Forklifts are essential in warehouses, construction sites, and industrial facilities, but they’re also a leading cause of workplace injuries when they are not properly maintained. A well-structured forklift checklist isn’t just a formality, it’s a frontline defense against costly accidents, compliance violations, and equipment failure.

In this guide, we’ll walk you through everything you need to know about daily forklift inspections, including what to check, how to do it, and why integrating digital solutions like Blaxtair can dramatically enhance your safety strategy.

Why Forklift Checklists Matter More Than Ever

According to the Occupational Safety and Health Administration (OSHA), forklifts are involved in nearly 100,000 accidents each year in the USA. Many could be avoidable, especially with solutions such as daily checklists.

Forklifts are powerful industrial tools, but when safety protocols are overlooked, they can become serious hazards. Daily inspections are essential to spotting mechanical issues early, preventing operator injury, and ensuring legal compliance.

Routine checks help:

- Prevent equipment failure that can lead to accidents

- Ensure proper operation, even in high-turnover shifts

- Keep workers and pedestrians safe in busy environments

In the U.S., OSHA mandates daily or pre-shift inspections for forklifts. Failing to document these checks could lead to regulatory penalties, costly repairs, and even worksite shutdowns.

At Blaxtair, our mission is to enhance workplace safety through AI-driven perception technology. By integrating forklift checklists with smart, real-time pedestrian detection, we help businesses reduce risks before they escalate.

What Is a Forklift Checklist?

A forklift checklist is a standardized form that ensures critical components of a forklift are inspected before each use. It covers both physical and functional aspects of the vehicle to verify its mechanical soundness and help maintain optimal safety.

There are two main types:

- Printable checklists: Paper-based forms filled out manually by operators.

- Digital checklists: Connected systems accessed via tablets or smartphones, often integrated into platforms like Blaxtair’s.

The industry is steadily moving toward smart checklists, which offer trackable records, alerts, and integration with other safety data. These systems not only ensure compliance but also provide valuable insights for proactive maintenance and risk management.

Forklift Daily Checklist: What to Include

Pre-Operation Checks (Visual)

Before turning on the ignition, operators should perform a visual inspection of the forklift. Key points include:

- Tires: Check for proper inflation and signs of wear or damage

- Forks: Ensure they are straight, not cracked or bent

- Seatbelt: Verify functionality and condition

- Mast: Look for cracks or deformities

- Overhead Guard: Inspect for any damage that could compromise operator safety

- Warning Devices: Lights, alarms, and backup beepers should be functional

- Fluid Levels: Check oil, hydraulic fluid, and coolant

- Leaks: Visually inspect the area under the forklift for any signs of fluid leaks

- Attachments: Ensure any specialized equipment is securely fastened and functioning

Operational Checks (Performance)

Once the forklift is running, a series of operational checks should follow:

- Brakes: Test parking and service brakes

- Horn and Lights: Confirm visibility and audibility

- Steering: Check for smooth response and unusual noises

- Hydraulics and Tilt Controls: Verify lift, tilt, and lower functions

- Load Handling: Confirm that forks raise and lower smoothly

- Emergency Controls: Make sure stop switches and kill switches are functional

Environmental & Safety Features

The inspection should also extend to the immediate work area:

- Obstructions: Ensure travel paths are clear

- Pedestrian Zones: Make sure safety markings are visible and respected

- Smart Detection: Use solutions like ‘Blaxtair Pedestrian Detection’ to monitor dynamic safety zones in real time and prevent collisions between forklifts and pedestrians

Printable vs. Digital Forklift Checklists: Which One to Use?

Printable Checklists

Pros:

- Easy to distribute and implement across small teams

- No training or internet connection required

- Ideal for sites where digital adoption is still in progress

Printable checklists are useful for establishing a routine inspection culture and creating a physical paper trail. They also serve as a compliance safeguard during OSHA audits.

Digital Checklists (Smart Safety Tools)

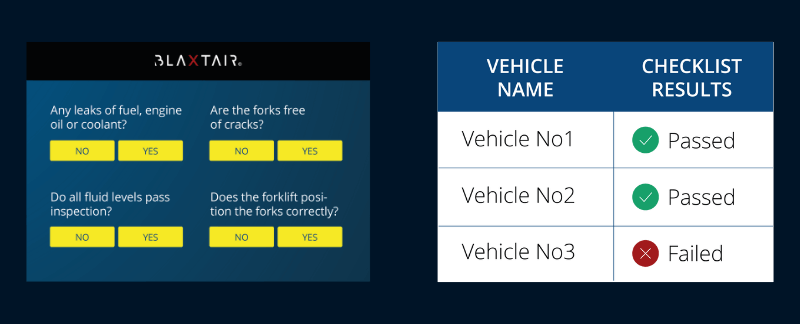

For organizations aiming to level up their safety protocols, digital checklists offer a smarter, more secure solution. Tools like Blaxtair Checklist go beyond basic reporting by integrating inspection logs with real-time data storage, incident tracking, and access control features.

With Blaxtair Checklist:

- Operators are guided step by step through customized safety questions when starting their forklift or construction vehicle.

- If a failure is detected or a critical safety question is not answered correctly, the vehicle can be blocked from starting, preventing unsafe operation.

- Maintenance teams are quickly alerted to fleet status, ensuring faster intervention and better fleet availability.

- All data is securely stored in the cloud, ensuring compliance and easy access for safety audits and performance reviews.

- The system is adaptable to any vehicle type, and aligns with regional regulations, including OSHA requirements in North America.

5 Key Benefits of Blaxtair Checklist:

- Workplace safety boosted: Operators complete a safety check before each use, drastically reducing the risk of preventable forklift accidents.

- Full cloud connectivity: Fleet-wide visibility and remote monitoring, with GDPR-compliant data privacy standards.

- Higher vehicle uptime: Early issue detection enables proactive repairs and keeps operations running smoothly.

- Lower maintenance costs: Addressing small issues before they become critical reduces breakdowns and long-term expenses.

- Digital traceability: Inspections are automatically logged, giving safety managers a clear overview of compliance and trends, far more reliable and accessible than manual records, which can be incorrectly completed and lost.

Pro Tip: Pair Blaxtair Checklist with the Blaxtair Pedestrian Detection System for a full-circle approach to industrial safety, covering both the vehicle’s condition and its environment in real time.

How Forklift Daily Checklists can Prevent Common Accidents

Daily forklift inspections catch problems before they become dangerous. Real-world data reveals that many workplace accidents occur due to issues that could have been flagged earlier:

- Worn brakes: Lead to uncontrolled movements or crashes

- Hydraulic leaks: Result in unexpected fork drops or handling failure

- Damaged seatbelts: Increase injury risk in tip-over incidents

- Obstructed view: Leads to collisions with other vehicles or pedestrians

Digital checklists not only ensure these issues are caught—they also automatically log failures, generate alerts, and track recurrence over time. This empowers fleet managers to act fast and target recurring risks.

OSHA Compliance and Checklist Requirements

The Occupational Safety and Health Administration (OSHA) requires that forklifts be inspected at least once per day under standard 1910.178(q)(7). For operations running multiple shifts, inspections are required before each shift begins.

Non-compliance can lead to:

- Fines or penalties

- Liability in case of an accident

- Loss of operating licenses in severe cases

Blaxtair’s connected system helps businesses:

- Maintain digital records to prove compliance

- Send alerts when checks are skipped or failed

- Escalate critical failures to supervisors automatically

Best Practices:

- Standardize your checklist format across locations

- Set digital reminders for operators

- Monitor inspection trends and incident rates via dashboards

Real-World Use Case: Smart Forklift Safety in Action

Companies that combine digital checklists with AI-powered pedestrian detection systems consistently report stronger safety outcomes across their operations.

Among the most common improvements observed:

- A noticeable drop in near-miss incidents thanks to better operator awareness and real-time alerts

- Faster detection and resolution of technical issues through automatic maintenance notifications

- Greater accountability and audit-readiness due to centralized digital recordkeeping

- Increased confidence from safety managers, knowing daily inspections are completed and traceable

Digital tools don’t just digitize the checklist, they transform it into a living, proactive safety mechanism. By integrating inspection routines with intelligent vision systems, companies can shift from reactive safety practices to a predictive, data-driven approach that reduces risks across the board.

Upgrade Your Forklift Safety Strategy Today

Forklift safety starts with daily discipline. A structured checklist ensures your equipment is ready, and your people are protected.

To recap:

- Use printable checklists for basic implementation

- Adopt digital checklists for long-term compliance, advanced monitoring and safety analytics

- Integrate with AI-powered systems like Blaxtair for full-spectrum safety

Want to take your forklift safety to the next level?

- Explore Blaxtair’s AI-driven forklift safety solutions

- Contact our team for a free demo or consultation